Profit growth with air humidity control

Inconsistent temperatures and humidity levels affect the physical condition and characteristics of wood because of its hygroscopic nature. In order to ensure a consistent product and avoid damaged products, it is therefore important to control the temperature and the air humidity. Here's how:

Wood is a hygroscopic material, sensitive to inconsistent temperatures and levels in humidity. If the air humidity is too low, it will make wood release water molecules, which leads to cracking, warping, and other issues that make the wood unfit for production.

Thus, fluctuations in temperatures and humidity levels affect the physical condition of hygroscopic materials. Whether it is for construction, decoration or other uses – it is vital that wood is always stored and aged correctly to ensure that it does not shrink, crack or warp.

Controlling the environment is critical in any type of production involving wood – sawmills, window, door, and furniture production, building component construction, wood veneer manufacture etc.

How correct air humidity can increase productivity in the wood industry:

- Consistent and high-quality products

- Less waste of the raw material increases profit

- Protection of wood during the entire production run

- Dust reduction to protect both machinery and people

- Uniform drying, maturation and ageing of products

Wood’s moisture content and relative humidity

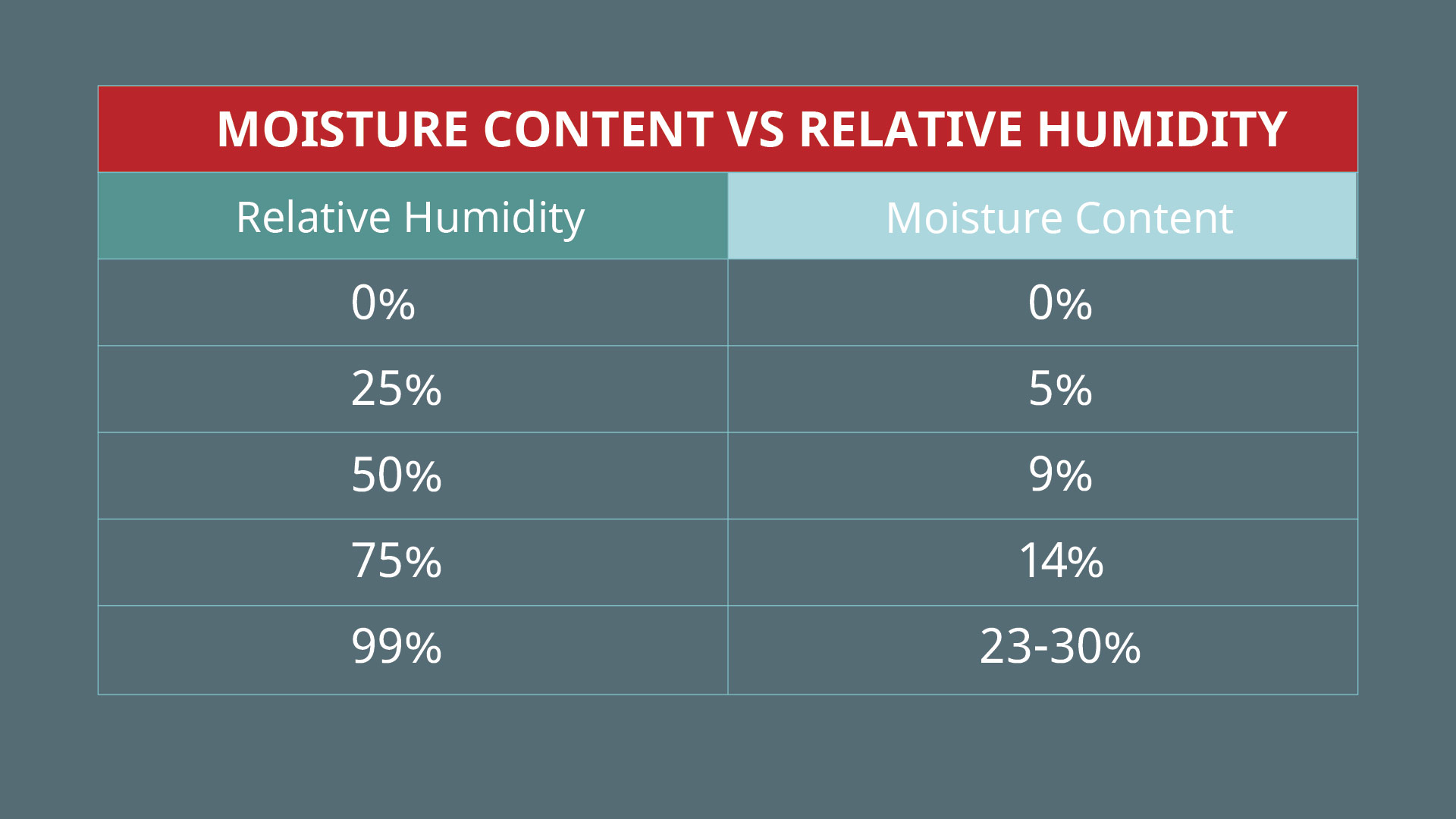

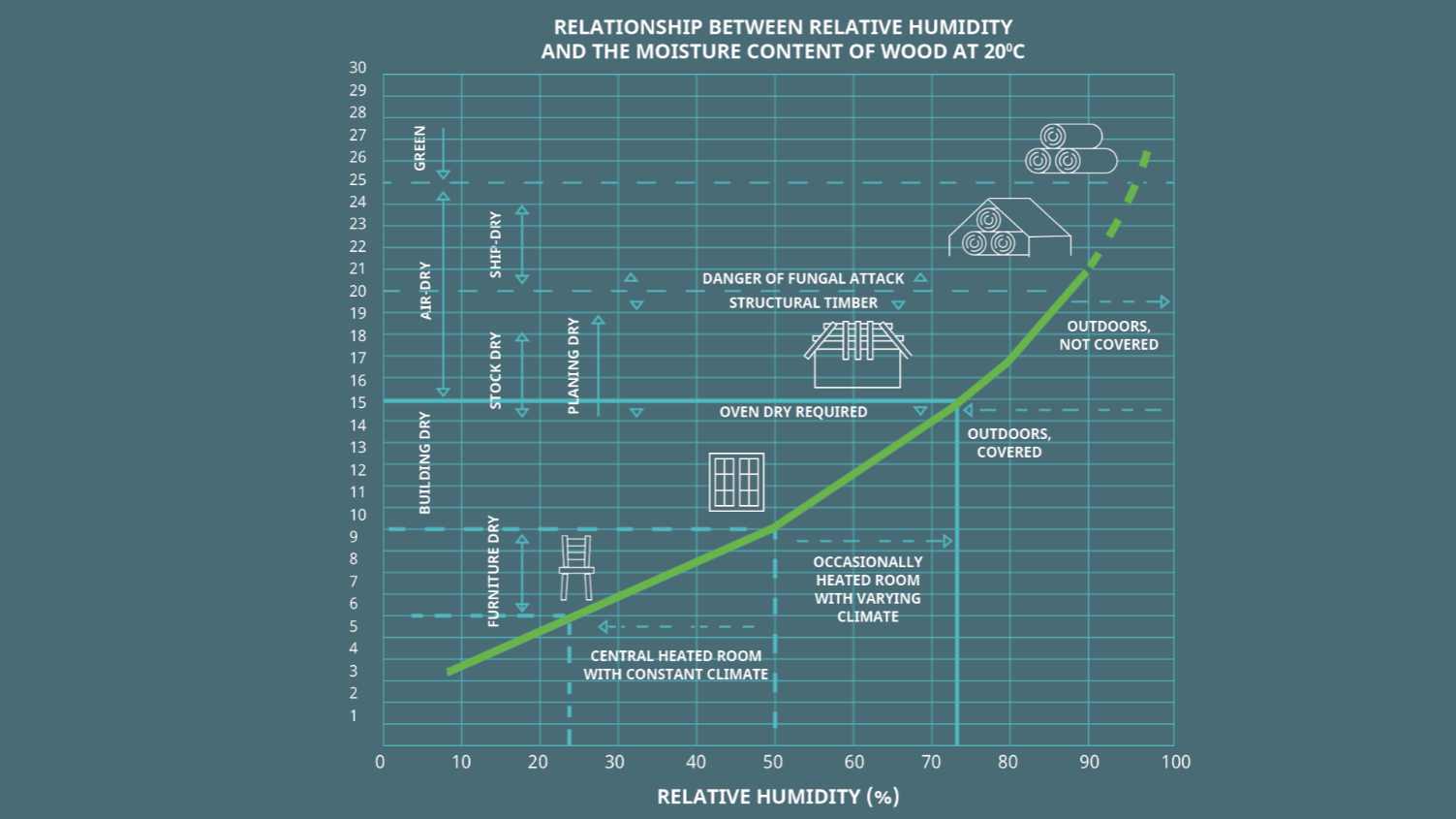

The moisture content of the wood is directly tied to the relative humidity of the ambient air. This means that the moisture content [MC] will increase with a higher relative humidity, and it might take a while for material placed in a new environment to reach its equilibrium moisture content (EMC) with the air.

This is important to keep in mind when working with construction wood that has recently been transported. The wood may take on more moisture or it may dry out, which will change the physical condition of the material.

For example, if wood at 10% MC is exposed to 25% RH, the wood will dry to 5% MC, hereby, shrinking as it dries.

Wood working and dust control

Air humidifying technology can have a positive effect in storage as well as in the production process. But there are other uses for this type of technology.

In sawmills and other industries processing wood, dust reduction is of the essence in order to protect machinery and to maintain a good working environment for personnel.

One way of controlling dust in production facilities is to use an industrial air humidifying system from Airtec®, designed, installed and maintained by experienced professionals.

This diagram shows how wood stored at 20° C changes its moisture content according to the way it is stored. The vertical axis represents the moisture content of the wood. There are six distinct levels of dryness in wood ranging from "green" wood with a moisture content in excess of 25% down to "furniture dry" wood with a moisture content of 5 - 9%. Ensuring a constant relative air humidity is essential in keeping wood or wood products in perfect condition without shrinking or warping.