Desiccation: How to avoid loss of product weight and quality

Air humidity – or, strictly speaking, relative air humidity (RH) – is a crucial factor in almost all process industries such as food production, wood working and chemical industry. In such industries, the raw materials as well as the finished products are naturally hygroscopic – i.e. they tend to lose or absorb moisture in response to the relative humidity of their surrounding environment.

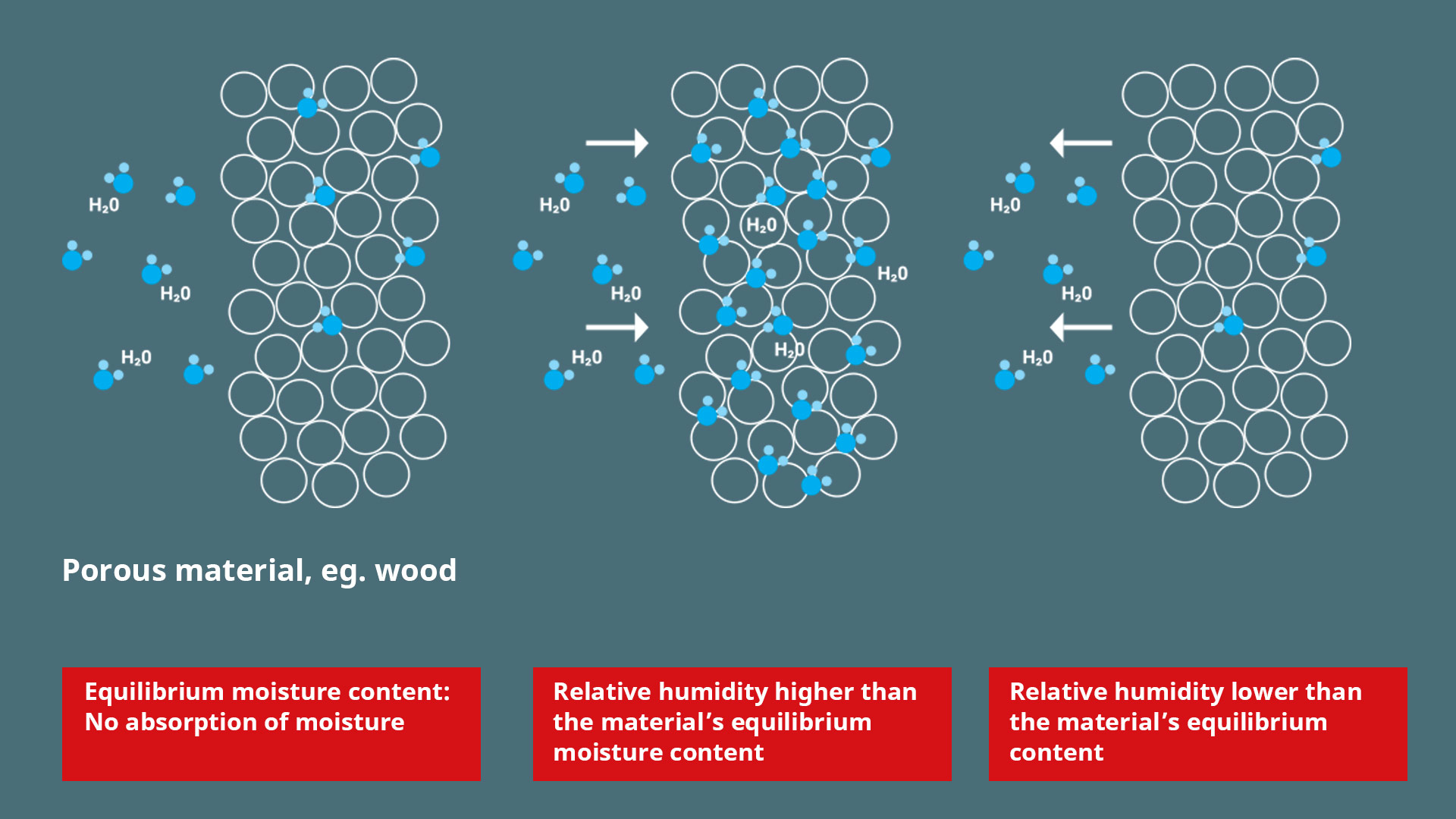

A material that is in balance with its surrounding atmosphere is said to have reached its equilibrium moisture content (EMC). When stored correctly, such a material and its surrounding air will be at equilibrium relative humidity (ERH), meaning that a stable state of affairs has been reached. However. changes in air temperature and relative air humidity will immediately move the equilibrium point, calling for both temperature and humidity control.

Desiccation is an important factor in the maturation and seasoning of products – there would be very little Parma ham in the world without controlled desiccation of meat, and very little usable construction wood without proper drying-out of the freshly cut material.

But it’s a fine balance between a controlled production environment and loss of product quality. If the relative air humidity drops below a critical point, products will become useless and must be discarded.

Hygroscopy – the sponge effectRaw materials such as wood, cellulose fiber (such as paper and cardboard), sugars, salts and several polymer compounds are naturally hygroscopic. This means that they will absorb and release moisture from the surrounding environment whenever they can. It also means that they will lose moisture if the surrounding air is drier than the product – the hygroscopic material and its surroundings (e.g. the atmospheric air) will find an equilibrium of humidity at all times. In a sense, a hygroscopic material acts like a sponge.

|

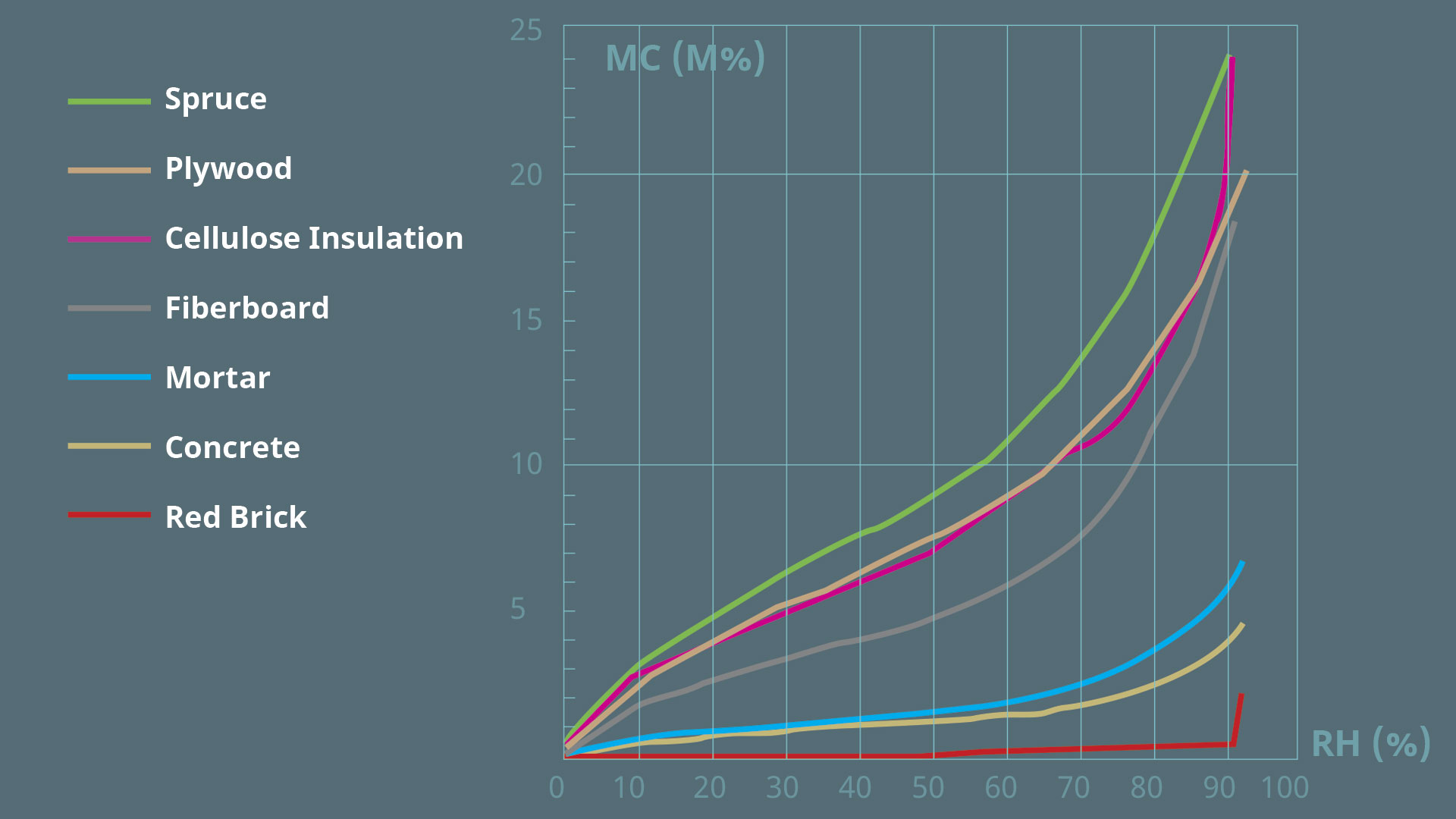

The amount of water in a hygroscopic product depends on the relative air humidity (RH) of its surroundings. The value of a material’s hygroscopic properties is usually defined as its CME – coefficient of moisture expansion.

This graph gives you the overview of the CME of some common materials:

Source: BuildingScience.com

Wood needs seasoning

Wood straight off the sawmill can have a water content of up to 30%; if the relative air humidity is too low, the wood will immediately begin to lose moisture. In fact, wood acts like a sponge – and will release its moisture to the air in case of low air humidity.

The correct amount of moisture increases the wood’s ability to withstand mechanical forces. Well-seasoned wood has reached an equilibrium point in which the wood’s natural hygroscopic affinities are kept in check, allowing the wood to keep its shape – in fact, construction wood that is kept under climatic control has a life span measured in centuries.

Furthermore, seasoned wood is much less vulnerable to degradation due to fungus or insects – in other words, it has become biologically stable. This is why seasoning of wood is a vital process in any industry based on wood – furniture, instrument making, construction etc.

When wood is exposed to a constant relative humidity (RH), it will eventually reach its equilibrium moisture content (EMC). The wood will stay at this humidity level as long as temperature and relative air humidity stay constant.

As an example, the moisture content of plywood at 25° C is:

6% EMC at 40% RH

10% EMC at 70% RH

28% EMC at 100% RH

This is one of the many reasons why the wood industry often air humidifying systems: To maintain a relative air humidity consistent with the correct seasoning and storage of wood products. If the relative humidity is too low, the wood will not season, but will dry out.

The results can be a complete write-off of the product: Warping, cracking and uncontrollable dimensions can lead to any wood product becoming worthless. In the wood working industry, maintaining the right air humidity is quite simply a question of ensuring the highest levels of productivity and of keeping product waste to a minimum.

The moisture content of a piece of wood is the total amount of water (or moisture) contained in that piece of wood. Moisture content is measured as the difference between the mass of wood with moisture “m” and without moisture “mod” (oven-dry mass), divided by the mass of wood without moisture “mod”:

Moisture content = (m – mod)/mod

Moisture in wood is either free water (water in cavities in the wood) or bound water (intercellular water). When no free water is left, the wood is said to have reached its fiber saturation point.

The optimum relative air humidity in wood production is typically 50 – 60% and must be kept within these limits throughout the year.

Less beef: Why air humidity matters in food production

All food items will lose moisture to the ambient air unless the relative air humidity is kept at a correct level – which varies greatly from product to product.

Strict control of air humidity will allow products such as cheeses to mature at a desired rate – for most cheese products, a relative air humidity of 75 – 95% is ideal.

If the air in meat storage is too dry, it is not uncommon for the weight of a meat product to drop by as much as 4% - a loss most producers would want to avoid.

Keeping air humidity up

Airtec® air humidifying systems are designed to maintain relative air humidity at a very precise level at all times, safeguarding your productive environment.

Airtec’s project engineers are experts at designing an air humidifying solution for any type of hygroscopic product. We often begin with a site assessment, in which we evaluate the layout of a production facility, the specific requirements of the raw materials and the finished products, and the existing ventilation and heat sources in the production facility. In this phase we work closely with our customers who possess the in-depth knowledge about their production processes and the ideal conditions for the product in question.

This gives us a very strong indication of where and how an air humidifying system could be used to make the facility much more productive, reducing downtime and avoiding destruction of products or equipment.

Airtec® will often work closely together with suppliers of dehumidifying or desiccation equipment to arrive at the ideal solution for food processing plants.

See how we’ve done it for others

Airtec® has decades of experience in planning, installing and servicing air humidifying systems – take a look at our case stories here.